Innovation in building homes

Prefabrication & Multi-joint Lock System Structure

Let's learn about the structure "Prefabrication & Multi-joint Lock System".

PD House Home Building Centre has created and chosen the most effective construction procedures. Also known as Prefabrication and Multi-joint Lock System construction, with engineering design and quality control at every step of production from the plant. From a team of skilled engineers with over 20 years of expertise who prioritise perfection. Prefabrication and Multi-joint Lock System are better to cast-in-place building technologies, resulting in high-quality homes with long service life.

Advantages of Prefabrication & Multi-joint Lock System

With engineering design and quality control at every stage of production from the factory, a team of specialist engineers with more than 20 years of experience emphasises accuracy superior to cast-in-place building technologies, ensuring quality and lifespan in every home.

Prefabrication & Multi-joint Lock System (MLS)

Reinforced concrete pre-cast foundation

Reinforced concrete pre-cast foundation is used for assemble J-Bolt to support from the column and transfer to the pile.

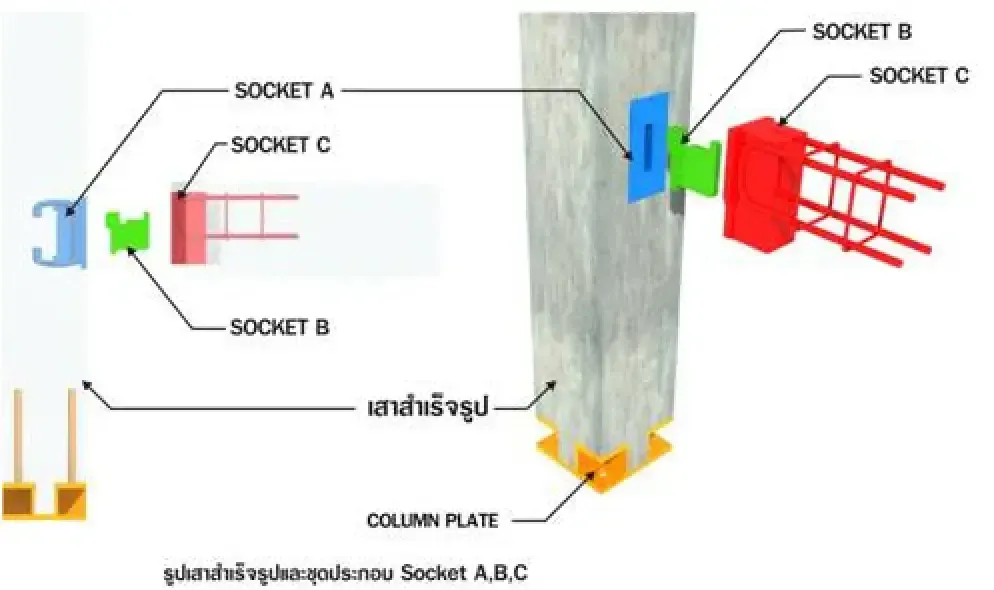

Pre-cast column

Pre-cast column is a reinforced concrete structure size and shape as engineer designed .It is used to support the load from the beam and transfer to foundation.

Pre-cast beam

Pre-cast beam is a structure which can be produced into two types. They are reinforced concrete beam and pre stress concrete beam. It is usually designed a one span beam not connected.

Pre-cast stairs

Pre-cast stairs are made to the length of stairs span, mostly are smooth back. The reinforced concrete for the stairs contains more steel to ensure safety when transport, install because it is easily damaged.

Pre-cast bathroom floor

Pre-cast bathroom floor is the same size of the bathroom with sanitary tubes are installed at the location of the sanitary wares.

Standard solid plank pre-cast floor panel

When fully constructed, the structure meets PD House specifications.